ADVANCED ANALYSIS / TEST

ELFR (Early Life Failure Rate)

- Acceleration stress conditions provide thermal and electrical acceleration conditions during operation, causing initial failure

- The purpose of evaluating thermal and electrical problems during operation, generally process or design problems, should be found, and the product should be operated to predict failure-in-time (FIT) and mean time to failure (MTTF) in the market using acceleration factors (temperature and voltage) to estimate the life of the product.

Conditions of progress

Early Failure Rate Duration / Temperature

| JEDEC(Industrial) | AEC-Q100(Automotive) |

|---|---|

| 48 Hrs ≤ t ≤ 168hrs , 125℃ ≤ Tj , Vcc Max | Grade 0: 48 hours at 150 °C or 24 hours at 175 °C , Vcc Max |

| Grade 1: 48 hours at 125 °C or 24 hours at 150 °C , Vcc Max | |

| Grade 2: 48 hours at 105 °C or 24 hours at 125 °C , Vcc Max | |

| Grade 3: 48 hours at 85 °C or 24 hours at 105 °C , Vcc Max | |

| Grade 4: 48 hours at 70 °C or 24 hours at 90 °C , Vcc Max |

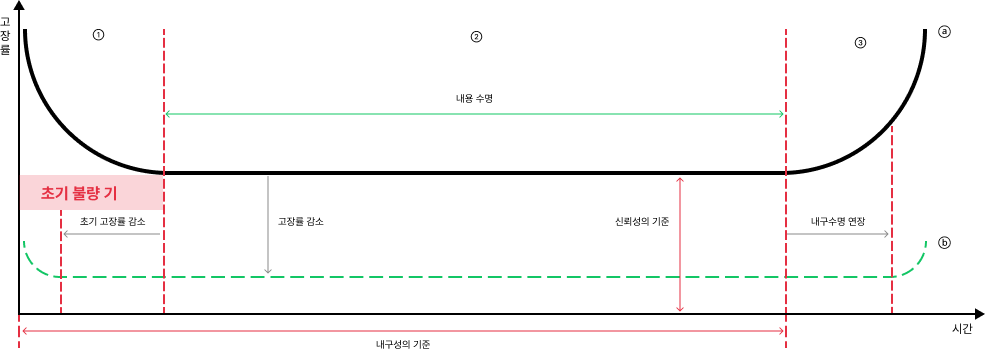

Bathtub curve

▶ Initial defector: Section where fixing or potential defects occur due to various processes and environmental instability during semiconductor manufacturing

▶ Initial defector: Section where fixing or potential defects occur due to various processes and environmental instability during semiconductor manufacturing

- Accelerated stress conditions provide thermal and electrical acceleration conditions during operation, causing initial defects, which can occur in the ELFR section in an early stage, eliminating potential defects. Screen by applying stress to detect future defects in the current state